- Home Page

- Company Profile

-

Our Products

- Aluminum Products

- Aluminium Scrap

- Aluminum UBC Scrap

- Aluminum Casting Scrap

- Industrial Aluminium Scrap

- Aluminium Brake Shoe Scrap

- Aluminium Casting Scrap

- Recyclable Aluminium Scrap

- Aluminium Piston Scrap

- Aluminium Radiator Scrap

- Aluminum Scrap

- Recycling Aluminum Casting Scrap

- Aluminum Alloy Wheel Scrap

- Aluminum Scrap

- Aluminium Ingot

- Aluminium Break Shoe Scrap

- Aluminum Section Scrap

- Aluminum Extrusion Scrap

- Automobile Aluminium Scrap

- Aluminium Wire Scrap

- Aluminium Dross

- Recycling Aluminum Casting

- Stainless Steel Scrap

- Mild Steel Scrap

- Aluminium Notch Bar

- Aluminium Shots

- Mica Sheets

- Silica Sand

- Aluminium Die Casting

- Chromite Sand

- Cut Wire Shots

- Refractory Castable

- Perlite

- Graphite Crucible

- Calcined Petroleum Coke

- Aluminum Powder

- Ceramic Fiber Blanket

- Contact Us

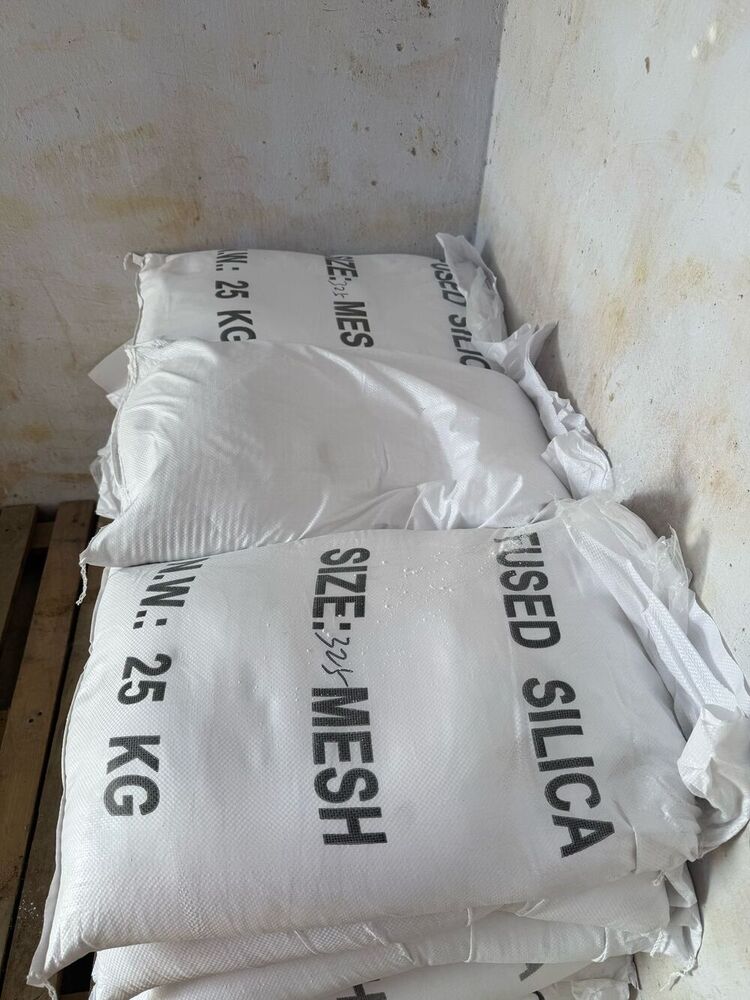

FUCED SILICA SAND

Price 80 INR/ Kilograms

MOQ : 501 Kilograms

FUCED SILICA SAND Specification

- Fineness

- 90-95% passing 600 micron sieve

- Weight

- 50 kg / 1000 kg Bags

- Compressive Strength

- Up to 60 MPa

- Color

- White to Off-White

- MgO %

- <0.3%

- Application

- Cement, Glass, Construction, Filtration, Foundry

- Bending Strength

- Up to 8 MPa

- SO3 %

- <0.2%

- Initial Setting Time

- >30 minutes

- Soundness

- <10 mm

- Cement Raw Material

- Silica Sand

- Cement Type

- Portland / Blended

- Sand Type

- Fused

- Sand Fineness

- Fine Grained

- Natural Sand Type

- Fused Silica

- Hardening Feature

- Rapid Initial Set, Uniform Hardening

- Heat of Hydration

- Moderate

- Product Strength Grade

- Industrial

- Shelf Life

- 12 Months

- SiO2 Content

- >99%

- Chemical Stability

- Excellent

- Thermal Conductivity

- High

- Al2O3 Content

- <0.02%

- Particle Shape

- Angular

- Packaging Type

- Bag / Bulk

- Bulk Density

- 1.50-1.60 g/cm³

- Moisture Content

- <0.1%

- Specific Gravity

- 2.65

- Solubility

- Insoluble in Water

- Usage Temperature Range

- Up to 1600°C

About FUCED SILICA SAND

Exceptional Purity and Particle Uniformity

With SiO2 content exceeding 99% and finely controlled fineness of 90-95% passing through a 600 micron sieve, Fused Silica Sand delivers superior quality for demanding industrial uses. Its angular particle structure and high bulk density enhance performance in cement, glass, filtration, and foundry applications by providing consistent blending and optimal mechanical properties.

Reliable Thermal and Chemical Performance

Engineered for environments requiring stability, this sand is characterized by excellent chemical inertness and high thermal conductivity, making it ideal for high-temperature industrial processes. Functional up to 1600C, Fused Silica Sand ensures enduring structural integrity throughout manufacturing or construction cycles.

FAQ's of FUCED SILICA SAND:

Q: How is Fused Silica Sand utilized in cement manufacturing?

A: Fused Silica Sand serves as a high-purity raw material for cement, particularly Portland and blended types. Its uniform particle size and high silicon dioxide content contribute to enhanced strength, rapid initial set, and consistent hardening, meeting the stringent demands of modern construction projects.Q: What benefits does the angular particle shape of this sand provide?

A: The angular shape ensures better interlocking and bonding within cement composites or foundry molds, contributing to greater compressive and bending strengths as well as improved durability and stability in finished products.Q: When should Fused Silica Sand be preferred over natural or regular silica sands?

A: It is ideal where high purity, uniform particle size, and low moisture are critical, such as in high-performance cements, specialty glass production, filtration media, and foundry casting where precision and strength are required.Q: Where does Fused Silica Sand find its primary applications?

A: This sand is primarily used in the manufacture of cement (as a raw ingredient), glass production, construction materials, water filtration systems, and industrial foundry operations, owing to its high purity and thermal stability.Q: What packaging options are available for Fused Silica Sand?

A: The sand is supplied in robust 50 kg bags for smaller projects or 1000 kg bulk bags for larger industrial requirements, ensuring ease of transport, storage, and handling.Q: How does the process of using Fused Silica Sand enhance product quality?

A: By introducing fine, uniformly sized sand particles with excellent chemical stability and low impurities, manufacturers can achieve higher compressive and bending strength, rapid setting times, and improved longevity in end-use applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Silica Sand Category

Quartz Silica Sand

Price 2500 INR / Ton

Minimum Order Quantity : 10 Tons

Color : Grey

Fineness : Fine

Product Strength Grade : Industrial Grade

Washed Silica Sand

Price 1200 INR / Ton

Minimum Order Quantity : 10 Tons

Color : White

Fineness : Fine

Product Strength Grade : Industrial Grade

Cement Raw Material : Other, Washed Silica Sand

Zircon Sand Zircon Flour

Price 200 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Color : Grey

Fineness : Fine

Product Strength Grade : Industrial Grade

Cement Raw Material : Other, Zircon Sand Zircon Flour

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese